Who are we

area

hours

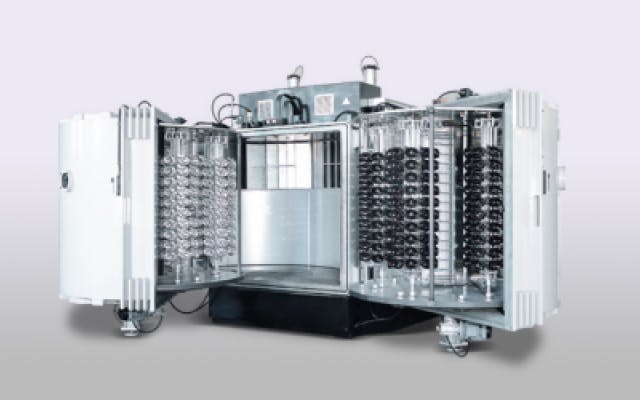

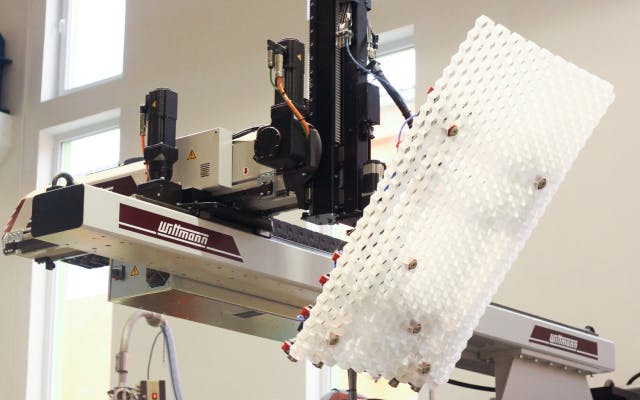

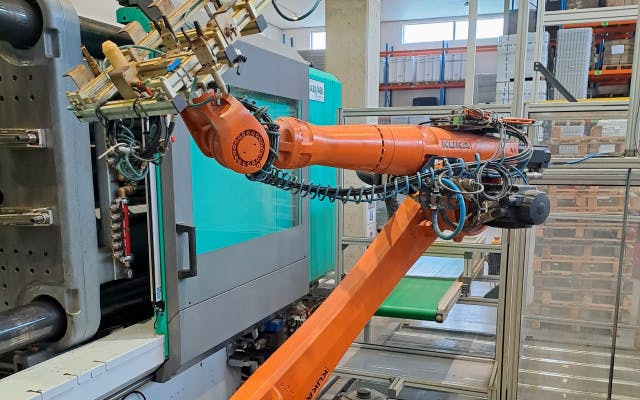

capacity

Over the past 30 years, we have become a modern, dynamic industrial company, specializing in the production of plastic parts with added value and in metalworking. We have thrived in both the Czech and international markets, continuing to develop the original vision of our founder, Slavoj Čegan, to build a Czech family company based in Šlapanice near Brno.

Our work is based on development and cultivation of long-term business-supplier relationships and partnerships, as well as on taking good care of our employees. We believe that innovation and creative ability to adapt flexibly to changing market environments and customer requirements are essential for further development or our own development. We strive to find new solutions and to put our knowledge into practice. The result of our work is a range of products that we have not only developed, tested, and patented, but also successfully brought to the market. The high technical level of our entire team is a testament to our innovation.

Among our main values are social responsibility and equal opportunities. Colleagues with disabilities are valuable members of our team at all levels of the organization. Since 2002 we have been a member of the Association of Employers of the Disabled in the Czech Republic (AZZP ČR), and within our capacities, we offer our business partners the supply of products and services in the form of facultative compensation.

Our Motto: People with disabilities can add the same value to a product as those without. None of us is as smart as all of us together.

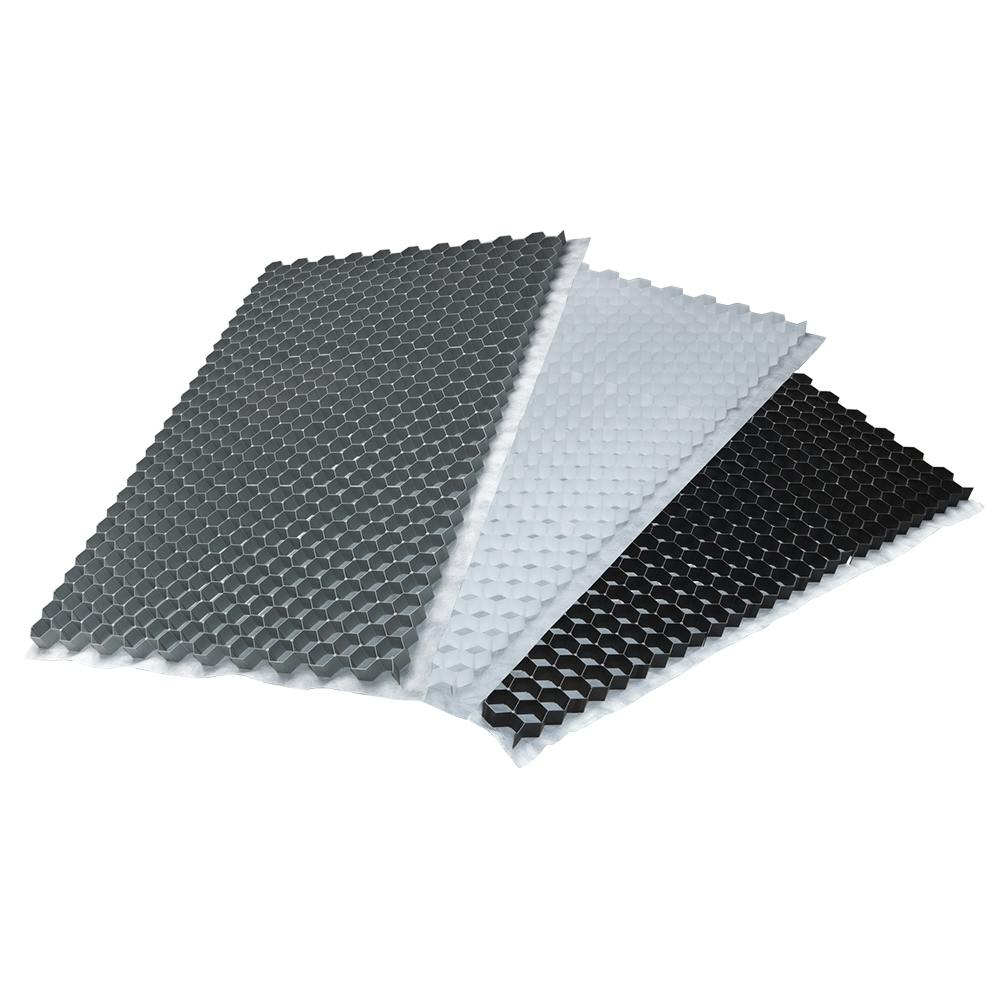

Another part of our strategy is the focus on efficient use of renewable resources and recycled materials. Our (current) photovoltaic power plant (0.6 MWp) covers approximately 20 % of the annual electricity consumption of the plant. We utilize waste heat from production for heating, and we use recycled materials for a portion of our product portfolio.